QM | Quality Management

Supports you in securing and improving your quality standards

The C3 Quality Management team will help you to ensure and improve process quality, services and hence your company’s products. Thanks to a large number of functions that can be integrated fully into enterprise resource planning and production, you can ensure your high quality standards with support provided to comply with directives for different certifications.

Your key advantages

- Support for ensuring and improving your quality standards

- Quality assurance test plans on production and shop floor

- Permanent continuous logging as a data basis for certification,

Customer and supplier audits as well as training/educational measures - Quality management as part of kaizen or the continuous improvement process

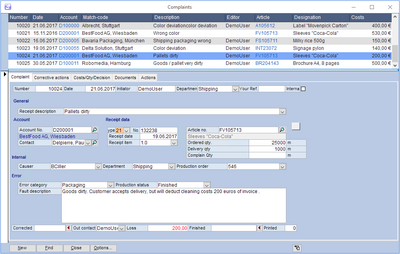

External and internal complaints can be recorded directly for customers or suppliers and linked to any other documents for handling further complaints and quality assurance.

Thus, for example, individual articles or tools can be barred, which are then treated separately when compiling the quote or order. Every error that has occurred and every complaint can be recorded and assigned to one of the freely definable error types and causes. The costs can also be saved for complaints. Analyses then show you the error types and resulting costs, with assignment to the relevant departments. In this way, the costs resulting from the “dust penetration” error type can typically be evaluated and then compared with the investment volume associated with suitable countermeasures.

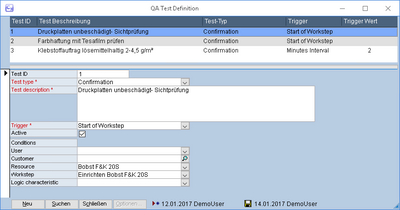

Quality assurance test plans are available in production and on the shop floor for the ever more important aspect of quality assurance during production.

To this end, tests can be defined, which typically have to be carried out by production staff under certain conditions and documented. The quality assurance tests can be defined to be carried out in relation to intervals or events and assigned to certain product properties or machines, customers or order properties. Simple “OK/Not-OK tests” through to measuring value logging with acceptable tolerances can be done as test types, among other options. The user is prompted via the user interface of the shop floor terminal to perform a certain QA test (e.g. “Monitor printing plates at the beginning of a work step” or “Measure film thickness every 1000 m”). A QA test record for a production order is generated as a result. This data can typically be used for compiling declarations of conformity.

All open and resolved complaints are available for every customer and supplier contact, along with all accompanying emails, photos, actions and documents. Quality assurance concerning suppliers is supported by automatically generated supplier ratings. Every supplier can be assessed according to any number of individually weighted quantitative quality criteria (for instance ability to meet deadlines, shortfalls or oversupply), or purely qualitative criteria such as complete delivery documents. The degree of fulfilment for delivery and quality classification regarding the supplier can then be derived from this.