Artificial Intelligence

Game changer for the production planning

Game Changer: Fully Automated Production Optimization with Artificial Intelligence

Smaller orders, shorter delivery times, greater material diversity: production planning is getting more complex and fast-paced, often requiring the "steady hand" of an experienced planner. This is now a thing of the past: using Artificial Intelligence, C3 optimizes the entire production planning process in a fully automated manner.

Your Key Advantages at a Glance

- Fully automated optimization of production planning powered by Artificial Intelligence

- Minimization of missed delivery dates and set-up times, maximization of machine capacity

- Automatic determinization of the best possible planning scenario

- Cloud computing for high performance

- Live key performance Indicators and statistics

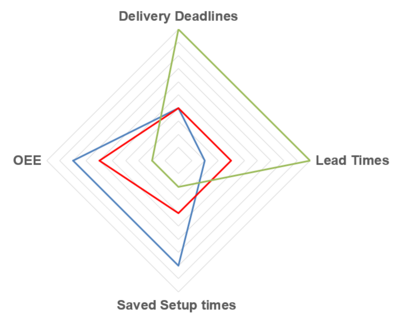

Artificial Intelligence (AI), as used in theurer.com C3, plays a crucial role in modern production planning. With its multidimensional optimization capability, it takes into account factors such as deadlines, setup times, capacity utilization and lead times to make production processes more efficient.

The challenge of production planning often lies in coordinating competing objectives. AI algorithms in theurer.com C3 master this task by finding the best trade-offs. They don't just deliver a static plan, but continuously adapt to changing conditions.

The benefits for employees are significant time savings and reduced planning complexity. AI automates tedious tasks, allowing teams to focus on strategic aspects. Overall, the integration of AI into production planning opens new horizons for more efficient and flexible production.

The optimum planning

The role of Artificial Intelligence in production planning is particularly evident when it comes to achieving "optimal planning". This goal encompasses several crucial aspects:

-

High on-time delivery: A key success factor in production is the timely delivery of orders. AI-based planning systems, such as theurer.com C3, optimize order processing so that as many orders as possible are completed on time or at least with minimal delay.

-

Less setup: Setup time is a bottleneck in many manufacturing processes. AI achieves this by determining the "optimal" sequence for jobs on the machines. This minimizes setup times and makes production more efficient.

-

Short lead times: Reducing lead times is not only cost effective, but also minimizes the amount of capital tied up and storage space required for semi-finished goods. AI systems can manage the flow of materials to minimize lead times.

-

High utilization: In production, idle machine time is often unavoidable. However, AI scheduling systems strive to keep idle time to a minimum. They optimize machine utilization and ensure that resources are used efficiently.

These goals compete with each other, often making manual planning a complex challenge. This is where AI comes in. It can strike the right balance between these goals to ensure optimal planning. Integrating AI into production planning opens up new dimensions of efficiency, flexibility and competitiveness in the manufacturing industry.

The benefits of AI-based production planning

Integrating Artificial Intelligence into production planning brings a number of key benefits that are making a difference in the modern manufacturing industry:

-

AI finds optimal planning: AI systems such as theurer.com C3 are able to achieve optimal planning by skillfully balancing factors such as on-time delivery, setup times, lead times, and capacity utilization. This holistic approach offers a clear advantage over conventional optimization logic, human planners and traditional sorting approaches.

-

Easy and regular rescheduling: One of the outstanding features of AI scheduling is its ability to quickly adapt to changes. In the event of new orders or unexpected disruptions, AI systems can perform optimal rescheduling, even if it means redesigning everything.

-

Lack of highly skilled workers: In highly specialized manufacturing environments, highly skilled labor is often limited. AI scheduling frees up these employees for more strategic tasks by taking over time-consuming planning. This increases efficiency and creates a competitive advantage.

-

Global planning: Instead of insular departmental approaches, AI planning enables holistic, cross-departmental planning. This fosters collaboration and improves overall efficiency as all processes are seamlessly aligned.

Overall, AI planning is revolutionizing the way production processes are planned and controlled. It provides not only optimal solutions, but also the agility to thrive in an ever-changing environment.

Fully automated production planning with AI: Maximum production efficiency

Fully automated production planning is a critical element in modern manufacturing processes, with a wide range of optimization goals. Key objectives include minimizing missed deadlines, reducing setup times, maximizing equipment utilization and effectiveness, shortening lead times, and minimizing overall delays.

This innovative planning method takes into account a variety of factors, including capacity and material availability, fixed dates and lead times, the so-called "frozen zone" (unchanging time periods), and alternative resources. All of these objectives and factors are weighted to ensure balanced and efficient production planning. In this way, fully automated production planning contributes significantly to increasing the overall efficiency and competitiveness of the manufacturing industry.

Different methods of Artificial Intelligence combined

C3 AI combines several of the latest theoretical methods from research and science and generates different planning scenarios for the user, e.g. minimizing delivery delays or maximizing plant utilization.

Dynamic global planning: on-time delivery and setup time savings

The result is automatically generated job schedules that are optimized considering delivery dates, material availability and replenishment times, setup time savings, and available capacity. New jobs can be dynamically scheduled at any time. Flexible machine configurations allow you to optimize all setup time factors. This means that you only need to set up your machines when absolutely necessary. Flexible weighting allows you to place more emphasis on current market demands, such as on-time delivery of major customer orders or minimum costs.

Live key performance indicators and statistics

Live statistics show the current KPIs such as setup time saved, number of delayed jobs, total late time, overall equipment efficiency, or whatever key factors you want to see. It’s your choice!

By the way: The enormous computing power for this AI application is provided by theurer.com in high-performance data centers via the cloud. Cloud computing for high performance.

Standalone Cloud Service and REST API integration

theurer.com production planning can be run with C3 ERP/MIS software or connected to your existing software solution.

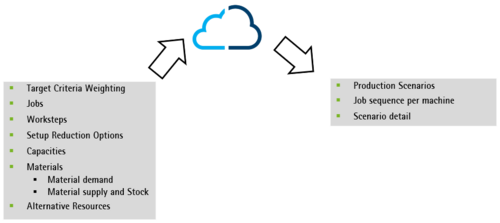

The AI engine runs in the cloud and can be accessed via an REST API. The basic input is a job list with job characteristics and deadlines, work steps with time and material consumption, and a shift calendar for resources.

Some features are optional, such as checking material availability. If required, a material list with replenishment time, stock level and purchase forecast must also be provided.

The result is planning scenarios that include a schedule for each resource with an exact start and stop time for each work step, including stored setup time.

Integration is easy and we are happy to support you with our experience and knowledge. You collect the inputs, call the REST API with them, get the optimal scenario, import and process this scenario in your system.