C3 Flexible Packaging & Converting is the pre-configured Business Template for flexible packaging, film manufacturing and converting within theurer.com C3 and is used all over Europe with great success. It contains pre-defined industry specific master data, business processes as well as reports and statistics and therefore ensures a fast project start. Also templates for estimating flexible packaging or film converting are included. The ERP/MIS Business Template therefore already offers a sophisticated industry specific base, which can be further optimized and automated by individual customizing.

Optimal for companies in these industries:

- Flexible packaging

- Film manufacturers & converting industry

- Manufacturer of roll products

Download Customer Report Ródenas & Rivera

Your key benefits

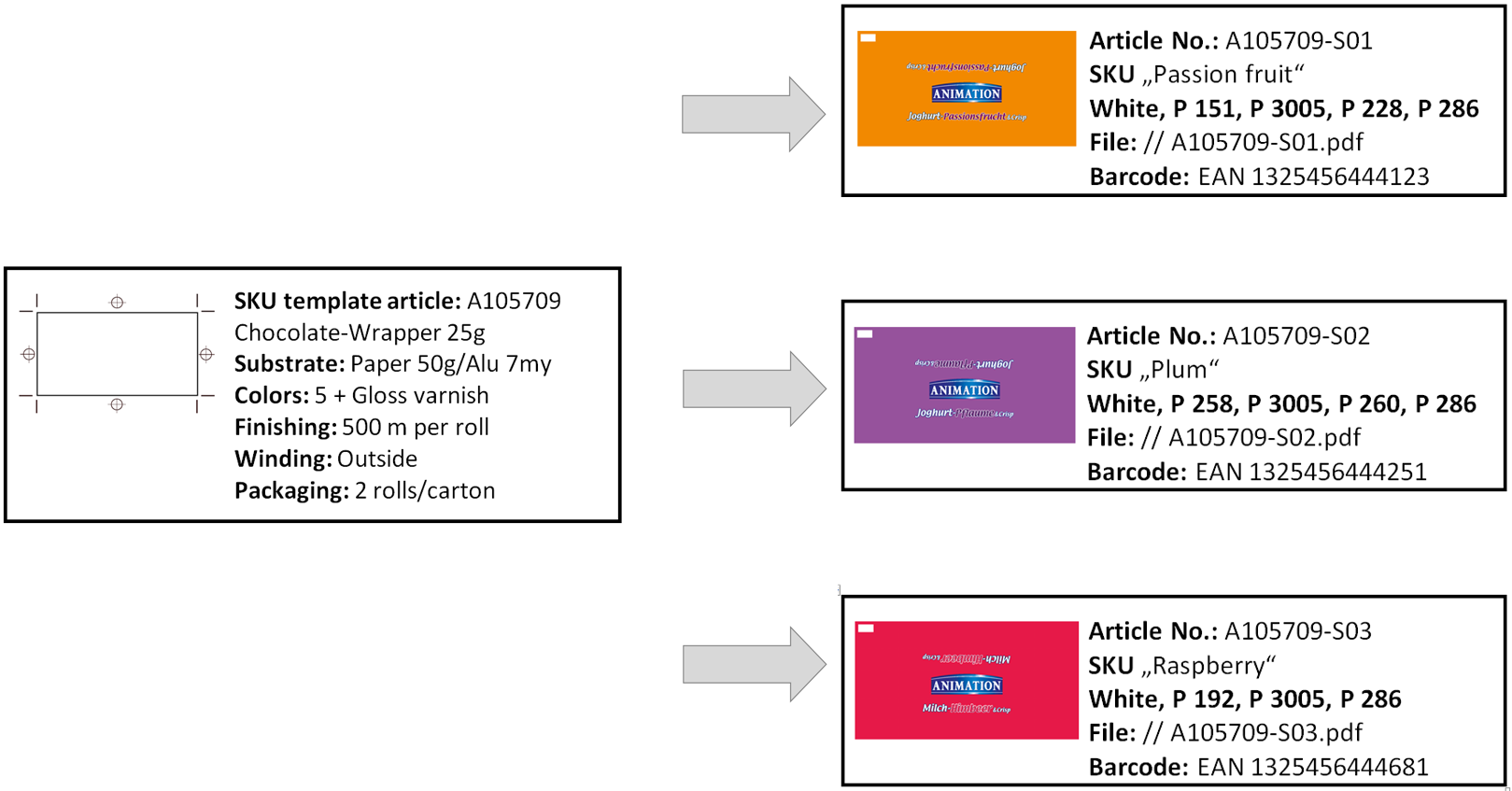

- Simultaneous comparative estimations (e.g. flexo/digital)

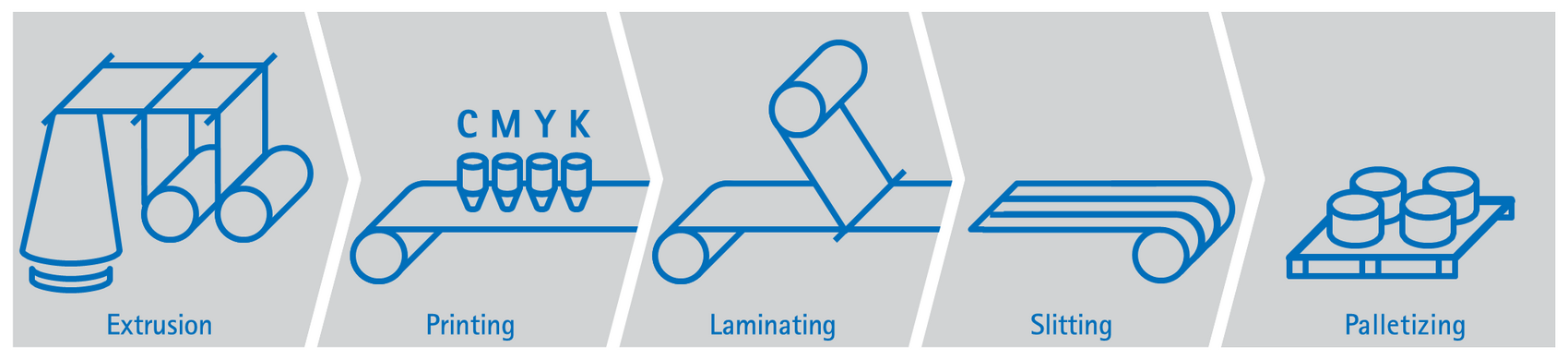

- Supports all processes: Prepress – Extrusion – Print– Laminating – Converting – Logistics

- Fully intergrated version (SKU) management for estimation, sales, logistics and production

- Seamless integration with many industry partners

- Material tracking and quality assurance

- Perfect roll stock handling

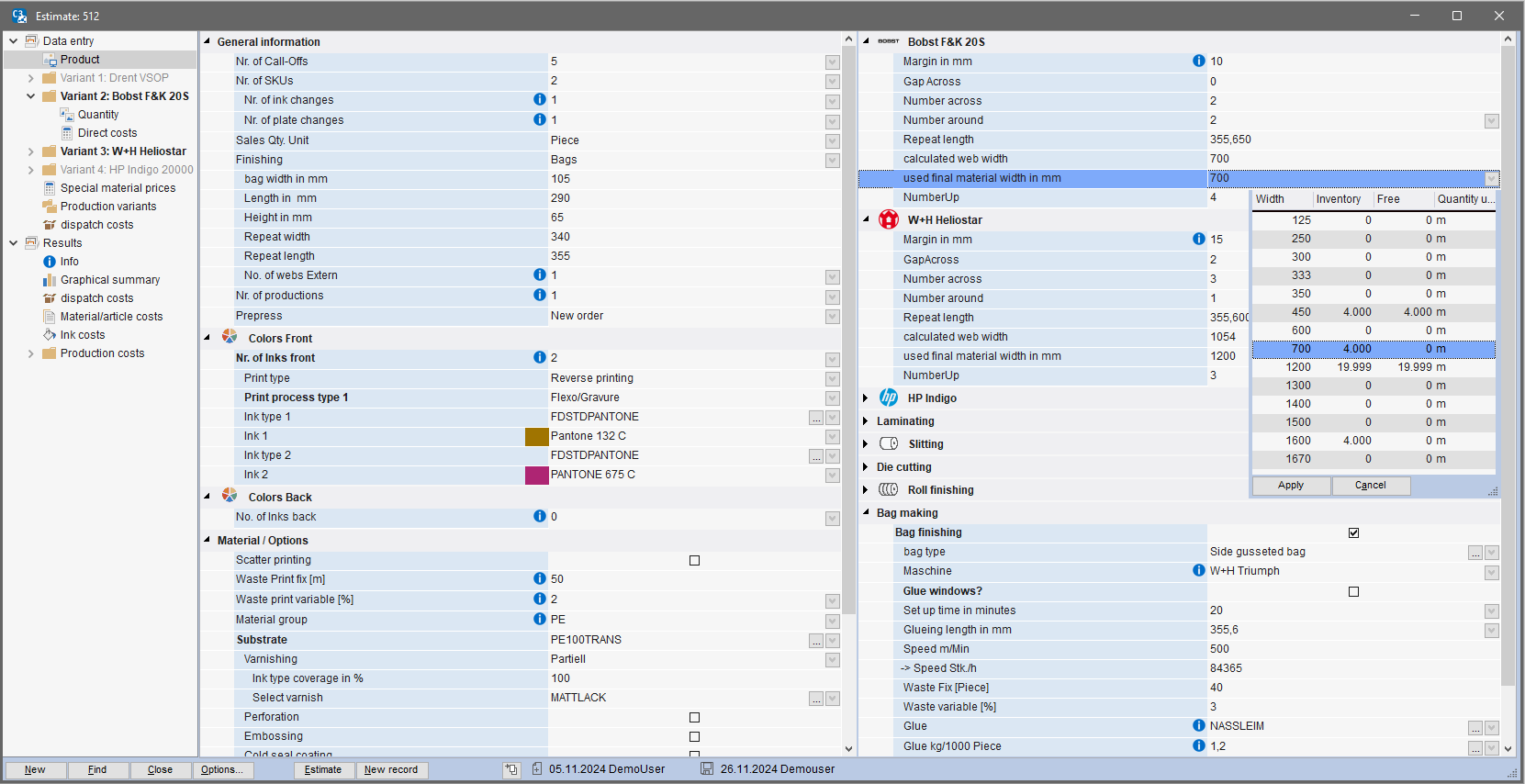

C3 offers fine-tuned version management to organize the various variants of a product. The product characteristics are segmented into features of the version (SKU) template (“Choco wrapper 25g”) and actual versions (“Plum”, “Rasperry",...). This gives C3 the ability to assess versions in terms of both calculation and production and simultaneously engage in separate consideration for sale, storage and logistics. Depending on the job requirements, C3 calculates with plate and color changes or gang jobs.

C3 lets you simulate and compare production on a range of different machines - e.g. flexo and digital printing. First and foremost, a configurable plausibility check helps determine the range of machines on which it would be technically feasible to manufacture your product. Subsequently, all production options that can be accommodated within this scope are simultaneously calculated at no extra cost. Finally, C3 proposes the most economical production option for each quantity.

This assistant “translates” a customer inquiry into feasible production methods, work steps and costs and creates a complete working plan as part of the process, including all costs and target values. Regardless of the quantities involved, the optimal production approach in each case is determined, e.g. HP Indigo 20000 or Bobst Flexo.

C3 makes managing all print forms, printing plates, sleeves or cylinders and their files a breeze. Print forms can be managed as complete printing plate sets or individually by color and type with the respective storage site. Depending on whether the print forms are produced in-house or externally, C3 provides support via production or ordering process.

The extrusion extension for C3 Flexible Packaging & Converting sets new standards in the production of flexible packaging films and offers a wide range of functions to optimize your production processes.

The product configuration and estimation of films become more precise and efficient, allowing you to automatically calculate material costs and production time. This significantly improves your planning and cost control. You can create diverse production variants that encompass different layers and features. This flexibility enables you to offer customized products without compromising efficiency. Efficient recipe management is ensured by the ability to define and manage layers, component groups, components, and alternative components. This facilitates the adaptation of your production processes to changing requirements and ensures high product quality.

Tracking recipe changes during production contributes to quality assurance and enables quick responses to unexpected challenges. The Extrusion Extension automates consumption bookings of recipe components such as granules, increasing the accuracy of consumption data and minimizing human errors. This allows you to manage your inventory more efficiently and avoid production bottlenecks. The extension also supports the re-granulation process, in which defective or surplus films can be recycled and reintegrated into the production process. This not only contributes to cost savings but also minimizes environmental impacts.

In summary, the extrusion extension for C3 Flexible Packaging & Converting provides a comprehensive solution to optimize your production of flexible packaging films.

Our customers must meet stringent quality, hygiene or pharmaceutical requirements such as BRC or GMP. Here, you can rely on C3 for guaranteed traceability among much more, allowing all materials, colors, semi-finished and completed products involved in production to be effectively traced, by batch or pallet. For materials supplied in rolls, individual roll management can also be activated.

C3 handles individual rolls and batches simply and efficiently and facilitates the process by allowing unique roll identification numbers to be assigned to each roll. During order production planning, this streamlines the process of procuring the required quantity of material from the warehouse or automatically ordering the same.

To maximize the workflow efficiency, we work with industry partners to automate numerous processes via JDF/JMF. For example, we leverage the Esko Automation Engine to bring you, e.g., complete JDF/JMF connections of the prepress workflow or give you access to digital printing workflows with e.g. HP Indigo

Standard films or composites, which are not made to order, are processed in C3 as intermediates. Items kept in storage at various stages of production, e.g. printed, laminated, ... are managed as semi-finished goods. For such semi-finished goods, processes can be organized for example so that certain production stages are only implemented when there is a call for delivery (“Bagging on demand”).

C3 lets you manage your mono or co-extruded formulas for film production with control over respective components as granulates, fillers or additives, giving you all you need to master material availability planning and traceability.

Specialized flexible packaging and converting features:

- Graphical display of roll winding

- Order specific roll planning with gross/net materials and different web widths

- Graphical impositioning and web width optimization

- Any quantity units like sqm, m, rolls, piece, kg and metric or imperial system

- JDF Integration Prepress-Workflow, e.g. Esko

- JDF Integration digital printing, e.g. HP Indigo

- Die amortization