C3 Label Printing is the pre-configured Business Template for narrow web labels and flexible packaging within theurer.com C3 and is used all over Europe with great success. It contains pre-defined industry specific master data, business processes as well as reports and statistics and therefore ensures a fast project start. Also templates for estimating labels or flexible packaging are included. The ERP/MIS Business Template therefore already offers a sophisticated industry specific base, which can be further optimized and automated by individual customizing.

Optimal for companies in these industries:

Your key benefits

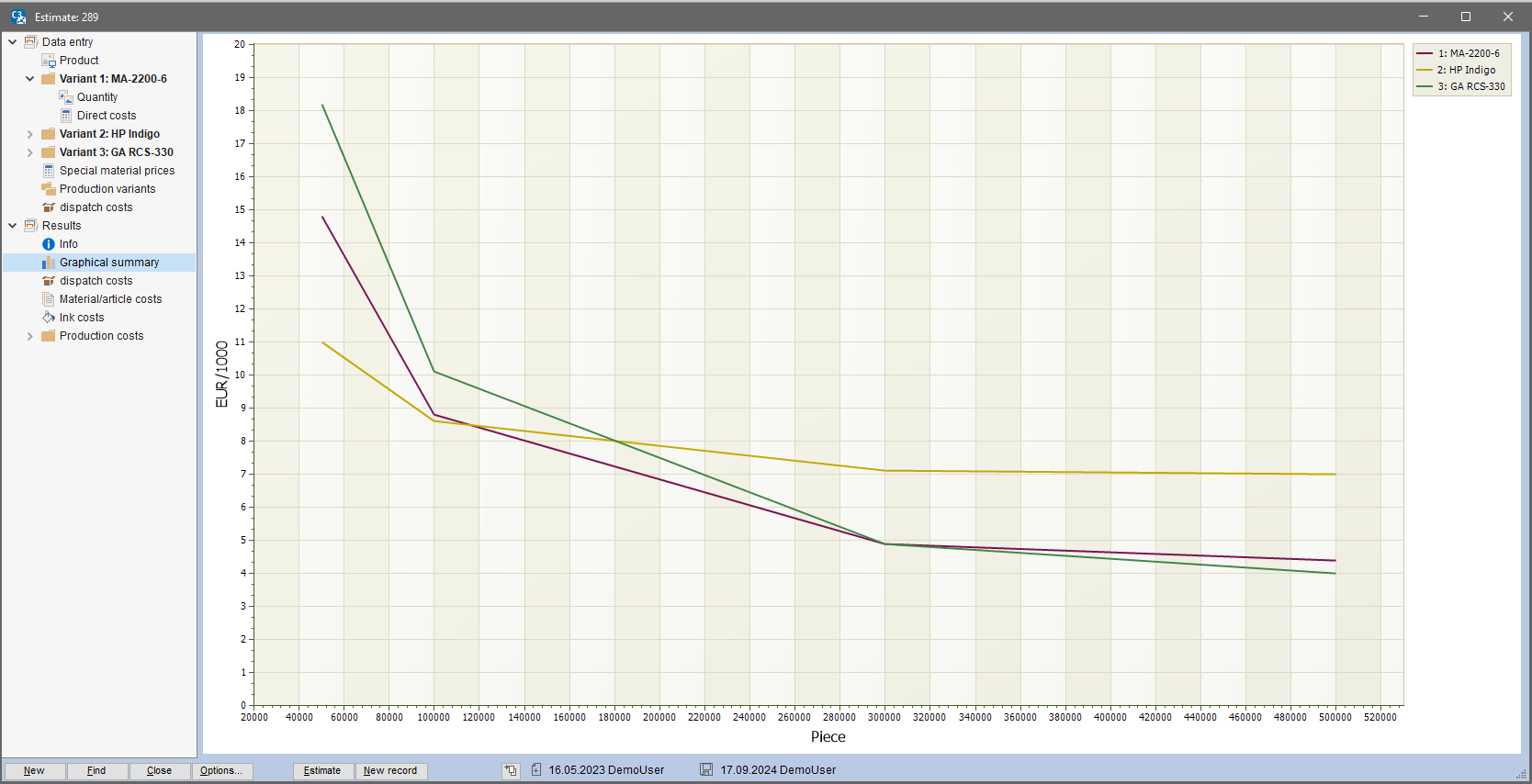

- Simultaneous comparative estimations (e.g. flexo/digital)

- Fully intergrated version (SKU) management for estimation, sales, logistics and production

- Seamless integration with many industry partners, e.g. Esko or HP Indigo

- Die management and roll stock tracking

- Web-to-print for labels and flexible packaging

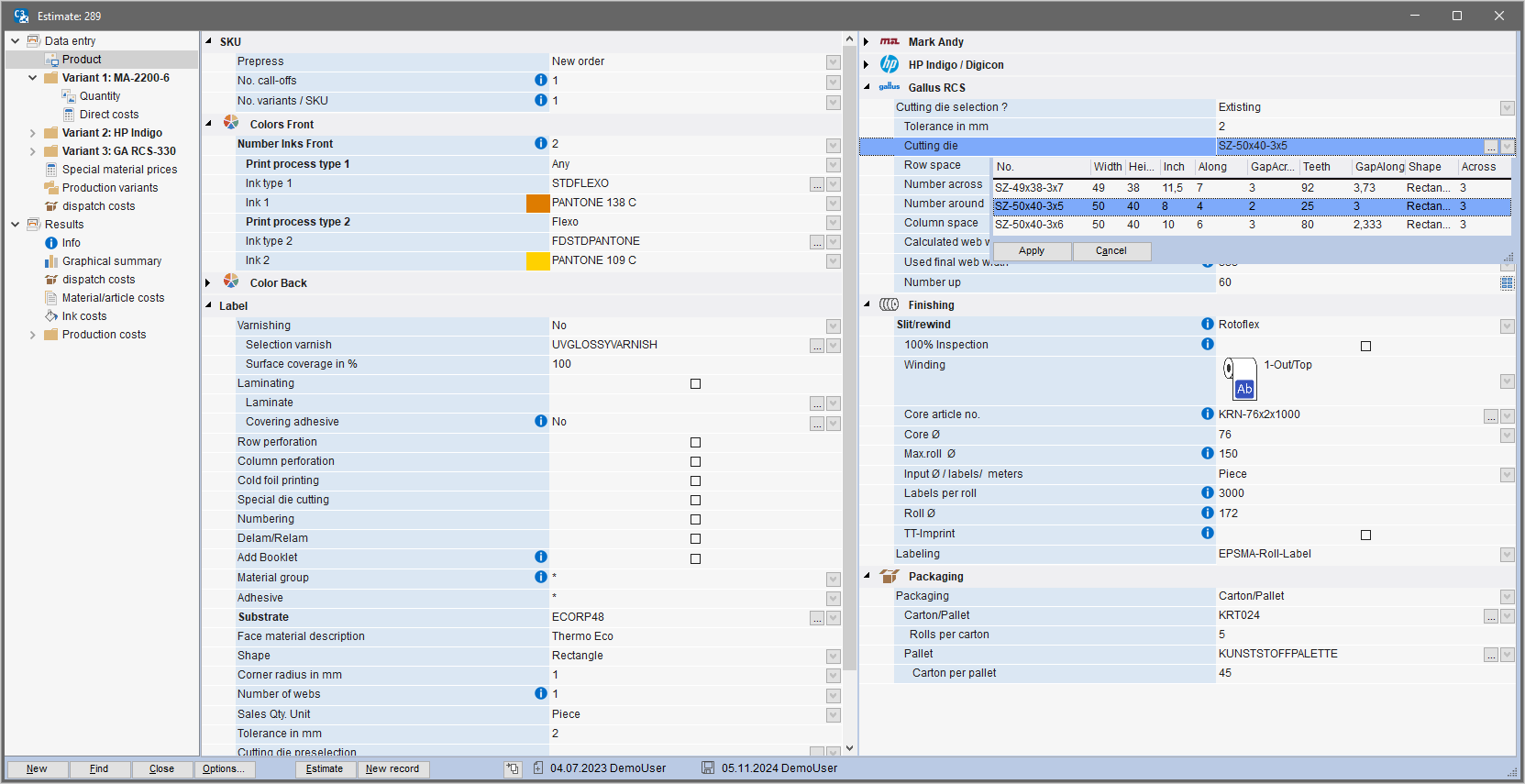

This assistant “translates” a customer inquiry into feasible production methods, work steps and costs and creates a complete working plan as part of the process, including all costs and target values. Regardless of the quantities involved, the optimal production approach in each case is determined, e.g. HP Indigo or Gallus RCS.

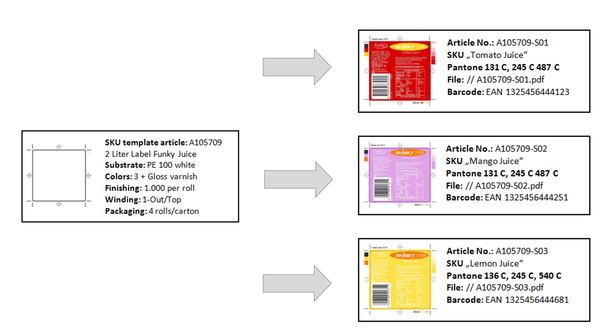

C3 offers fine-tuned version management to organize the different variants of a product. The product characteristics are segmented into features of the version (SKU) template (“2L bottle label”) and actual versions (“orange”, “lemon”,...). This gives C3 the ability to assess versions in terms of both calculation and production and simultaneously engage in separate consideration for sale, storage and logistics. Depending on the job requirements, C3 calculates with plate and color changes or gang jobs.

C3 lets you simulate and compare production on a range of different machines - e.g. flexo and digital printing. First and foremost, a configurable plausibility check helps determine the range of machines on which it would be technically feasible to manufacture your product. Subsequently, all production options that can be accommodated within this scope are simultaneously calculated at no extra cost. Finally, C3 proposes the most economical production option for each quantity.

C3 handles dies without any problem, as well as printing or die cut cylinders. Individual features can be assigned to each tool group – including Number up, gaps and suitability in terms of material – and supplementing company-specific features. This also paves the way to assign respective tools and cylinders to specific machines or machine groups. As early as the calculation stage, C3 gives you the full picture whether the required tools or cylinders are available and their location or whether procurement will be required. C3 can then leverage information in pricing tables to calculate the corresponding tool costs.

C3 optimizes every aspect of the prepress process management. The scope includes full control over the approval process in the C3 web portal or facilitating support in the form of conventional cover letter corrections. The deadline for approval of corrections can also be monitored by C3, while conversely, reminders for correction approval can also be sent directly by C3 itself. Via JDF, you can also link in your prepress workflow system, e.g. such as the Esko Automation Engine.

C3 handles individual rolls and batches simply and efficiently and facilitates the process by allowing unique roll identification numbers to be assigned to each roll. During order production planning, this streamlines the process of procuring the required quantity of material from the storehouse or automatically ordering the same. There is even room to automate the process further by integrating digital delivery and pallet slips of material suppliers. For each supplier, materials can be purchased in gross or net quantities and you can either specify a fixed range of widths for each material or let C3 generate the details automatically as required.

To maximize the workflow efficiency, we work with industry partners to automate numerous processes via JDF/JMF. For example, we leverage the Esko Automation Engine to bring you, e.g., complete JDF/JMF connections of the prepress workflow or give you access to digital printing workflows with HP Indigo or Xeikon. Likewise, business transactions with material suppliers can also be automated, e.g. via an interface to Fasson Connect.

Additional features at a glance

- Estimating narrow web labels

- Estimating flexible packaging

- Material traceability for regulation (EG) 178/2002, BRC, GMP

- Printing plate administration for sets or individual plates

- Logistics labeling: identification for GS 1 /SSCC with pallet slips, box labels,

roll labels or core labels - Roll planning: Assign actual rolls or rest rolls to productions orders

- Any quantity units like sqm, m, rolls, piece, kg, and metric or imperial system

- Managing dies, sleeves, cylinders

- Single roll stock administration (e.g. EAN-128 oder EPSMA)

- Order specific roll planning with gross/net materials and different web widths

- Material tracing and lod administration

- SKU and contract order managing

- Synchronizes call-off orders and production planning

- Winding pictograms on quotes, order confirmations, and internal documents

- Clever administration of material web widths

- Web-Portal for approvals, SKU management, call-offs, and estimating

- Graphical impositioning and web width optimization

- JDF Integration Prepress-Workflow, e.g. Esko Automation Engine

- JDF Integration digital printing, e.g. HP Indigo or Xeikon

- Integration material suppliers, e.g. Fasson Connect

- Decision tables for e.g. set-up times, press speed, and waste